Weather swings, disease spikes, and high feed bills eat profits fast. Stress that water, oxygen, and feed must be just right—and all the time. Smart environmental control, sensors, and automated feeders solve the chaos, cut waste, and keep fish (and shrimp) growing fast.

Aquaculture production rises when farms control water quality, feed timing, and system design. Using intelligent aquaculture systems—from RAS to marine cages—producers stabilize yield, lower costs, and meet strict market standards. That’s why leading fishery and aquaculture companies trust integrated climate, water, and feeding control to scale safely and sustainably.

Aquaculture production is the farming of aquatic animals and plants—fish, shrimp, shellfish, seaweed—under controlled conditions. Together, fisheries and aquaculture production feed billions. According to the FAO fisheries and aquaculture reports, global aquaculture production reached record highs as capture fisheries plateaued. In other words, aquaculture surpassed capture fisheries as the dominant source of aquatic animal protein.

For us, as a livestock breeding equipment manufacturing plant that also engineers aquaculture systems, this shift is personal: corporate buyers now demand robust, automated, and scalable aquaculture systems that protect margins and meet sustainability goals

Controlled environment aquaculture (think RAS, indoor tanks, precision ponds) lets you monitor and control oxygen, temperature, pH, and feed in real time. Compared to traditional earthen ponds, production systems with automation deliver:

Higher production per cubic meter

Lower production costs over time due to feed efficiency

Reduced environmental impacts of aquaculture (less discharge, better biosecurity)

Consistency—critical for contracts and export markets

This is the same logic behind controlled environment agriculture in greenhouses. In fish farming, water is your “climate,” and pumps, filters, sensors are your climate control system.

Systems offer dynamic control, meaning they adjust to environmental changes without waiting for manual checks. That’s precision farming underwater.

Whether you run freshwater aquaculture, marine aquaculture, or offshore aquaculture, the building blocks look similar:

| Component / System | Purpose | Example Tech Used |

|---|---|---|

| Recirculating Aquaculture Systems (RAS) | Reuse water, control waste | Biofilters, UV, oxygen cones |

| Feeding Systems (R/S Series Aqua-Feeder) | Accurate, timely feeding | Intelligent algorithm models, remote control |

| Sensor Systems | Track DO, temp, turbidity | IoT sensor arrays, cloud dashboards |

| Aeration & Oxygenation | Keep fish alive and active | Blowers, liquid oxygen injectors |

| Water Treatment | Remove solids, ammonia, CO₂ | Drum filters, degassers |

| Environmental Management | Integrate data & alarms | Smart Farm Net, PLC control units |

Marine aquaculture (offshore cages, coastal aquaculture) suits species like salmon, sea bass, or seaweed. Freshwater aquaculture (ponds, tanks) covers tilapia, carp, catfish, shrimp. Your choice depends on:

Aquaculture species biology

Local food production sector demands

Capital for RAS vs. lower-tech ponds

Regulatory and environmental conditions

Production level and production costs differ. Offshore aquaculture has high capex but premium species; freshwater aquaculture can scale cheaply but must fight disease and water pollution.

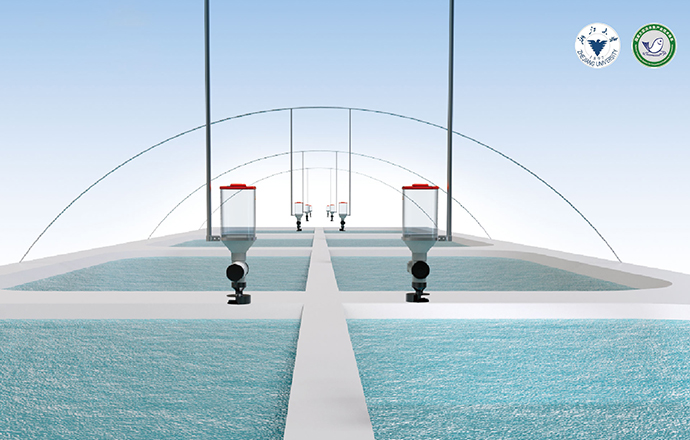

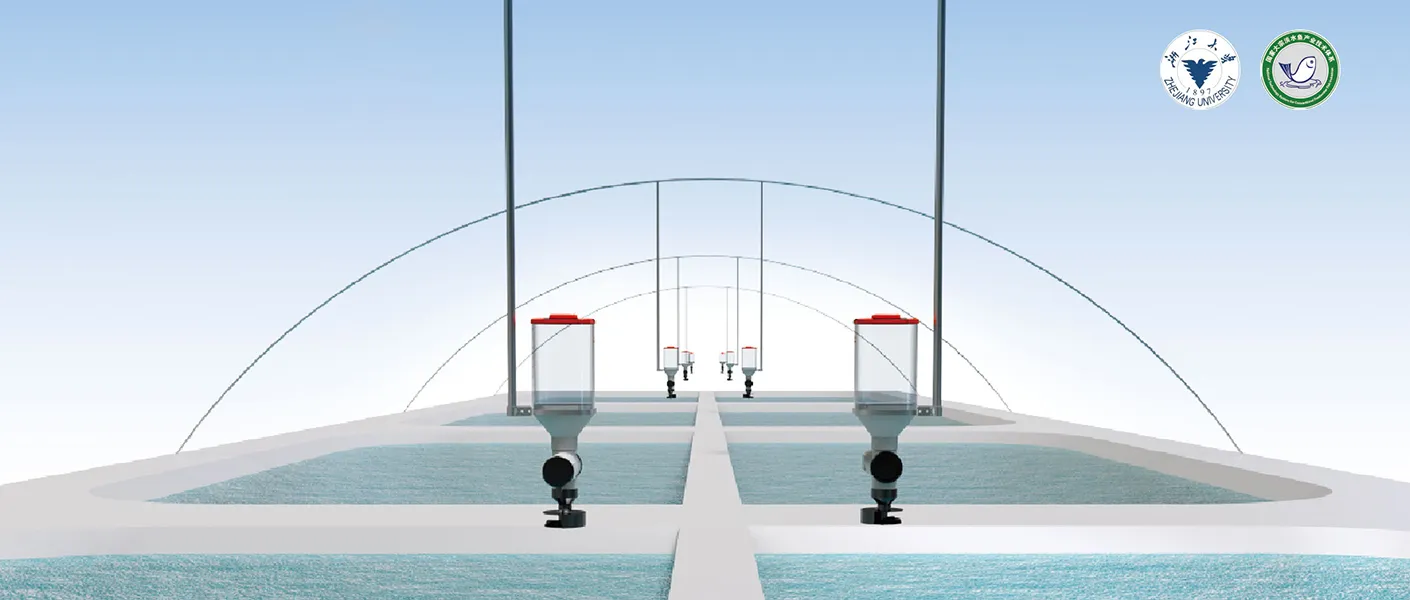

Big Herdsman R series aqua-feeder

Big Herdsman S series aqua-feeder

High feed bills? Labor shortages? Automated control systems answer both.

Our R Series Aqua-Feeder (rotary spread) and S Series Aqua-Feeder (spot precision) are built to increase production, cut production costs, and protect water quality. (See internal links below.)

Systems enhance resource efficiency, and systems help you reuse water, lower feed waste, and streamline the management of environmental variables. This protects local ecosystems and your brand reputation.

Corporate buyers—Poultry Production, Egg Production, Pig Production, Aquaculture Production, engineering contractors and agricultural technology service companies—want partners who:

As an established livestock breeding equipment manufacturing plant, we also build IoT-fed aquaculture systems—so we design control technology that works in harsh farm conditions, not just in brochures.

How does aquaculture production differ from capture fisheries?

Aquaculture production farms aquatic animals in controlled systems, while capture fisheries harvest wild stocks. Aquaculture offers predictable output and quality.

Is marine aquaculture more profitable than freshwater aquaculture?

It depends on species, market price, and capex. Marine species often fetch higher prices but require more complex systems.

What role does the FAO play in aquaculture development?

The FAO provides data, guidelines, and technical papers (e.g., FAO Fisheries and Aquaculture Technical Paper) to help countries build sustainable policies and practices.

Can small-scale aquaculture benefit from automation?

Yes. Even small farms can use low-cost sensors, automated feeders, and mobile dashboards to cut waste and improve growth.

How do recirculating aquaculture systems reduce environmental impacts?

RAS recycles water, reduces discharge, and allows precise control of waste, oxygen, and temperature—making operations cleaner and more efficient.

What’s the biggest challenge in aquaculture growth today?

High feed prices, disease risk, and climate instability. Smart control systems help manage all three by optimizing inputs and detecting problems early.