Expanding an egg farm is no longer just about adding more birds. Land, labor, energy, and biosecurity all limit your growth. This is why many professional egg producers choose a type A layer cage system: a proven, cost effective way to raise more layers in the same house while keeping management under control.

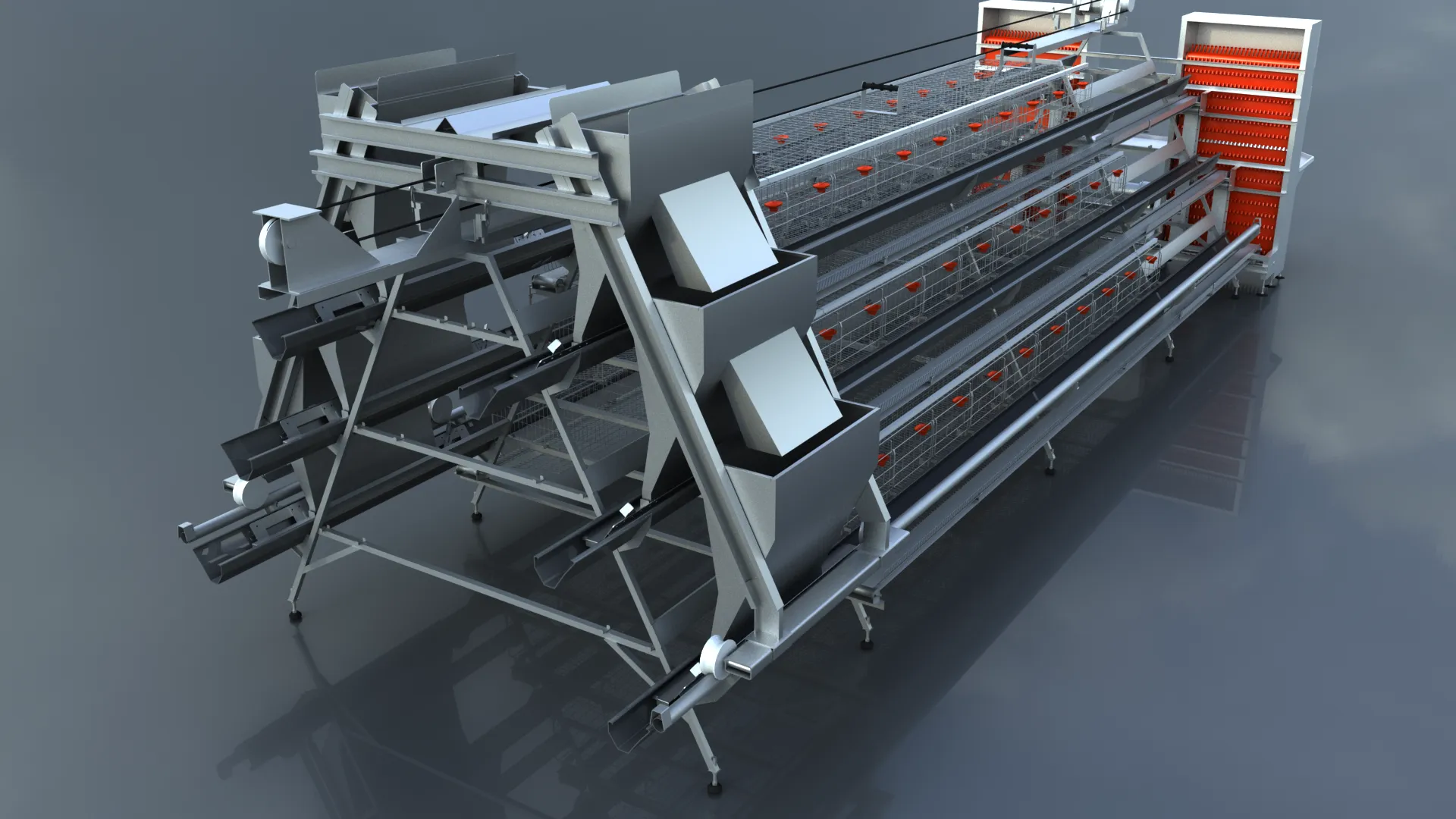

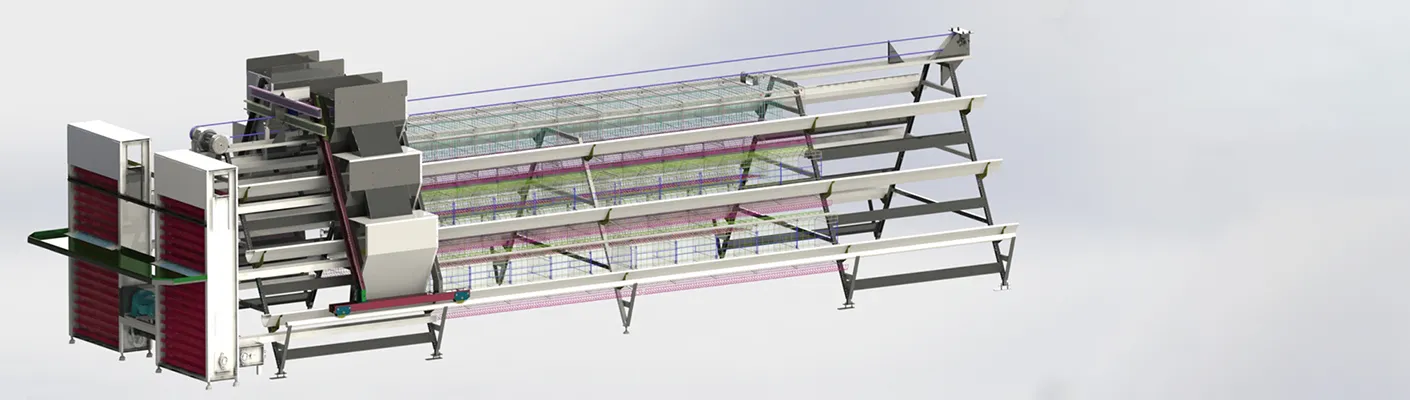

A type A layer cage (also called an A frame layer cage or A type layer cage) organizes hens in multi tier cages arranged in an A shaped structure. When combined with automatic feeding, drinking, egg collection, and manure removal, it becomes a complete housing solution for small to large commercial layer farms.

As Big Herdsman, a livestock breeding equipment manufacturer founded in 2005, we design and produce complete type A layer cage systems for global customers in poultry production, egg production, engineering contractors and agricultural technology service companies. Below, we explain what type A cages are, how they work, and how they help you build a more efficient egg business.

A type A layer cage is a cage structure where the cages are arranged in an A shaped frame when viewed from the side. Typically:

A complete type A layer cage system includes:

Compared with H type cages, a type A system is simpler in structure, easier to install, and often more suitable for farms upgrading from floor systems or for markets that prefer lower initial investment with solid performance.

Type A layer cage

Type A layer cages remain popular worldwide because they balance cost, simplicity, and productivity. For many farms, they are the first step from traditional floor or deep litter systems into modern commercial layer housing.

A type A layer cage uses:

This reduces the initial investment per bird, making type A layer cage systems attractive for small and medium scale farms, as well as for large farms that want to expand step by step.

Because the A frame is open on both sides:

This is especially helpful in markets where labor is available and farm owners are used to hands on management.

Type A layer cages can be installed in:

This flexibility allows farms in different climates and investment levels to select the right house type and gradually upgrade environmental control over time.

When converting a floor house to cages, type A cages often fit the existing building height and width better than tall H type systems. Civil modifications can be minimized, reducing project risk and cost.

As a manufacturer, we know that a type A layer cage is much more than steel and wire. Details in design and production strongly affect egg production, service life, and maintenance cost.

Depending on your farm design, type A layer cage systems can be equipped with:

Creating a dry, low ammonia environment around the cages is essential for bird health and shell quality.

The value of a cage system is measured in eggs per hen housed, feed conversion, and overall cost per egg. A well designed type A system supports these key performance indicators.

| Parameter | Floor System | Type A Layer Cage |

| Hen housed mortality | Higher | Lower (with good management) |

| Feed conversion ratio (kg feed / dozen eggs) | Less efficient | More efficient |

| Saleable egg rate | Lower (floor cracks, dirty eggs) | Higher (cleaner eggs) |

| Labor per 10,000 hens | High | Reduced due to simpler collection and cleaning |

While exact values depend on management, genetics, and nutrition, many farms see clear improvements in technical and economic performance after upgrading to a type A layer cage system.

A cage alone is not enough. To get the most from a type A layer cage, you need a coordinated house system. As Big Herdsman, we provide equipment and design for:

Depending on scale and budget:

Even when using type A cages in open houses, we strongly recommend:

This integrated approach makes sure your type A layer cage house works like a coordinated machine, not a collection of separate parts

As a livestock breeding equipment manufacturing plant, Big Herdsman offers more than just individual products. We focus on complete solutions for poultry production, egg production, and aquaculture production.

For type A layer cage systems, our strengths include:

This combination of manufacturing power and engineering capability makes us a reliable partner for turnkey layer cage projects, whether you are building a new farm or upgrading old houses.

Capacity depends on house length, width, tier number, and stocking density. For example, a typical house of around 80–100 meters fitted with 3 tier type A cages on both sides can house tens of thousands of layers. We calculate the exact number based on your building size and local regulations on birds per cage.

Yes. Type A layer cages can work very well in hot climates when combined with good ventilation and cooling systems. We often use tunnel or sidewall ventilation, circulation fans, and cooling pads to control temperature and humidity. The open structure of the A frame also helps air flow around the birds.

Yes. Many farms use type A layer cage systems in open sided houses with curtains. This is common in mild climates and regions where investment in fully closed houses is not yet necessary. However, even in open houses, proper fan placement and curtain management are important for good performance.

With hot dipped galvanized or high quality galvanized materials and correct management, type A layer cages can serve for many years and multiple flocks. Keeping manure away from the cage frame, controlling house humidity, and performing regular maintenance on moving parts all help extend the service life.

Yes. Many customers start with simpler systems—manual or semi automatic egg collection and basic manure handling—and plan to upgrade over time. When we design your type A layer cage house, we consider future upgrades so that adding automation later is easier and more cost effective.

If you are planning to upgrade from floor systems or build new egg houses and want a reliable, practical solution, a type A layer cage system from an experienced manufacturer like Big Herdsman can be the foundation of your next stage of growth.