El hombre que practica yoga

El hombre que practica yoga

Modern poultry producers frequently battle leaky drinkers and uneven water delivery. This causes health challenges, wasted resources, and lower profits. The solution is surprisingly straightforward: adopt a precision nipple drinker that ensures fresh drinking water, reduces spillage, and boosts flock performance.

A precision nipple drinker leverages stainless steel or plastic components to provide just the right flow rate to poultry. These systems minimize water wastage, improve litter conditions, and maintain optimal water pressure. By catering to the unique needs of birds—hens, broilers, and breeders—poultry farmers enjoy happier flocks, higher productivity, and healthier environments.

A nipple drinker system provides a direct water into the nipple approach that focuses on delivering fresh, clean water instantaneously whenever a bird taps the nipple. This reduces water spills and supports better hygiene in your gallinero. With each peck, the broiler or hen accesses precisely the amount of water needed, curbing wastage and promoting overall health.

In our experience as a manufacturer of poultry solutions, we’ve seen that such a drinker system is more reliable over time than conventional methods. The poultry can manage their own water requirement without reliance on open troughs or excessive dripping. Consequently, the environment remains dry, the litter is less soiled, and disease transmission rates typically drop. These advantages have made nipple systems one of the most popular forms of equipamiento avícola among modern avicultores.

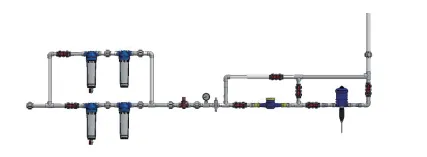

Water management is crucial because every poultry farm needs to save water and preserve cleanliness. A poultry drinking system integrates nipple drinker technology with carefully calibrated hardware, ensuring the perfect flow rate for your birds. This consistency supports a comfortable environment—there’s less drip and fewer puddles for pathogens to thrive in.

With the help of automatic flushing features, you can effectively flush out residue from the drinking line and guarantee fresh drinking water at all times. Moreover, controlling water pressure in the pipes ensures stable water flow, leading to uniform water delivery across the entire house. By maintaining a regulated water level, you eliminate stress on birds while promoting reliable hydration.

For broiler flocks, consistent access to sufficient water plays a key role in optimal growth and feed conversion. For broiler flocks, consistent access to sufficient water plays a key role in optimal growth and feed conversion. A well-designed drinking system includes broiler nipples or specialized poultry 360 degree nipple devices. These have a nipple design that responds to even slight pecking, improving your flock’s ability to consume water.

From our observations, broiler drinker is made with durable, precision machined stainless steel components that maintain a stable flow rate. This not only meets the needs of birds at every stage of development but also cuts down on chamber blockages. Additionally, the enclosed design prevents contamination, supporting better biosecurity in commercial poultry facilities.

Quality Craftsmanship with Precision Machined Stainless Steel

We pride ourselves on robust engineering. Each nipple or poultry drinker is built from stainless steel elements and cost effective materials, ensuring longevity in harsh farm environments. Our precision machined stainless steel parts stand up to heavy usage and extreme conditions while guaranteeing consistent performance.

Unlike generic store-bought accessories, our value drinkers incorporate a side action component that allows birds—be they broiler or breeder—to access water with minimal effort. This approach respects the birds’ natural pecking instincts, leading to more efficient hydration.

Trusted by Clients Worldwide

We’ve earned trust by supporting corporate customers from Poultry Production, Egg Production, and Aquaculture Production. As a livestock breeding equipment manufacturing facility, we fully appreciate the importance of advanced technology and reliable after-sales service. Our client base is large-scale, requiring stable, robust equipment that fosters long-term, profitable results.

We stand behind our products and cultivate ongoing cooperation—just as we do with engineering contractors and agricultural technology service companies. They seek consistent product quality, quick support, and professional expertise to keep their projects on schedule. By collaborating closely, we tailor our nipple drinker solutions to each unique operation.

Tailored Solutions Delivering Water Directly to Birds

Each poultry nipple we design features a multi-stage metering pin to control the amount of water dispensed. This ensures each peck yields exactly the right volume, whether dealing with newly hatched chicks or adult flocks. Birds quickly learn to draw water from the nipple with minimal spillage, and the enclosed system dramatically lowers contamination risk.

In certain setups, we incorporate breeder sistemas para beber or broiler nipples specifically adjusted for heavily muscled birds. This approach provides consistent water flow, making sure all birds get the hydration they need. Our nipple drinker technology also includes optional drip cups to catch leftover drops and keep the floor clean.

Additional Equipment and Integrated Systems

Alongside drinker solutions, we supply integrated packages. For instance, our Sistema de alimentación-Silo is an excellent companion, automating feed logistics and streamlining daily operations. We also offer Manual harvest cage system that simplifies egg collection and flock handling. By combining advanced feed, drink, and climate solutions, you manage your poultry environment holistically.

For bigger projects, we can bundle the poultry drinking system with a comprehensive approach: from Auto harvest cage system to Egg collection system-Single hole auto nest. The result is a coordinated farm design where water line, feed line, and ventilation align under a single control strategy.

Service That Goes Beyond Installation

Many portion their budgets solely for purchase and overlook aftercare; that’s a mistake. Because letter-perfect performance demands upkeep, our teams remain available for technical support, spare parts guidance, and expansions. We understand that stable water management and consistent hydration cannot happen without well-planned daily checks and occasional flush cycles.

“Invest in reliable systems once and watch how it pays off repeatedly every season.” That’s our philosophy, grounded in field experience and constructive feedback loops from clients worldwide.