Struggling with high mortality and low egg production in your poultry farm? Overcrowded spaces, messy environments, and outdated cage systems cause headaches for every producer. The good news: modern layer chicken cages solve these pain points with smart design, boosting productivity, hygiene, and flock health.

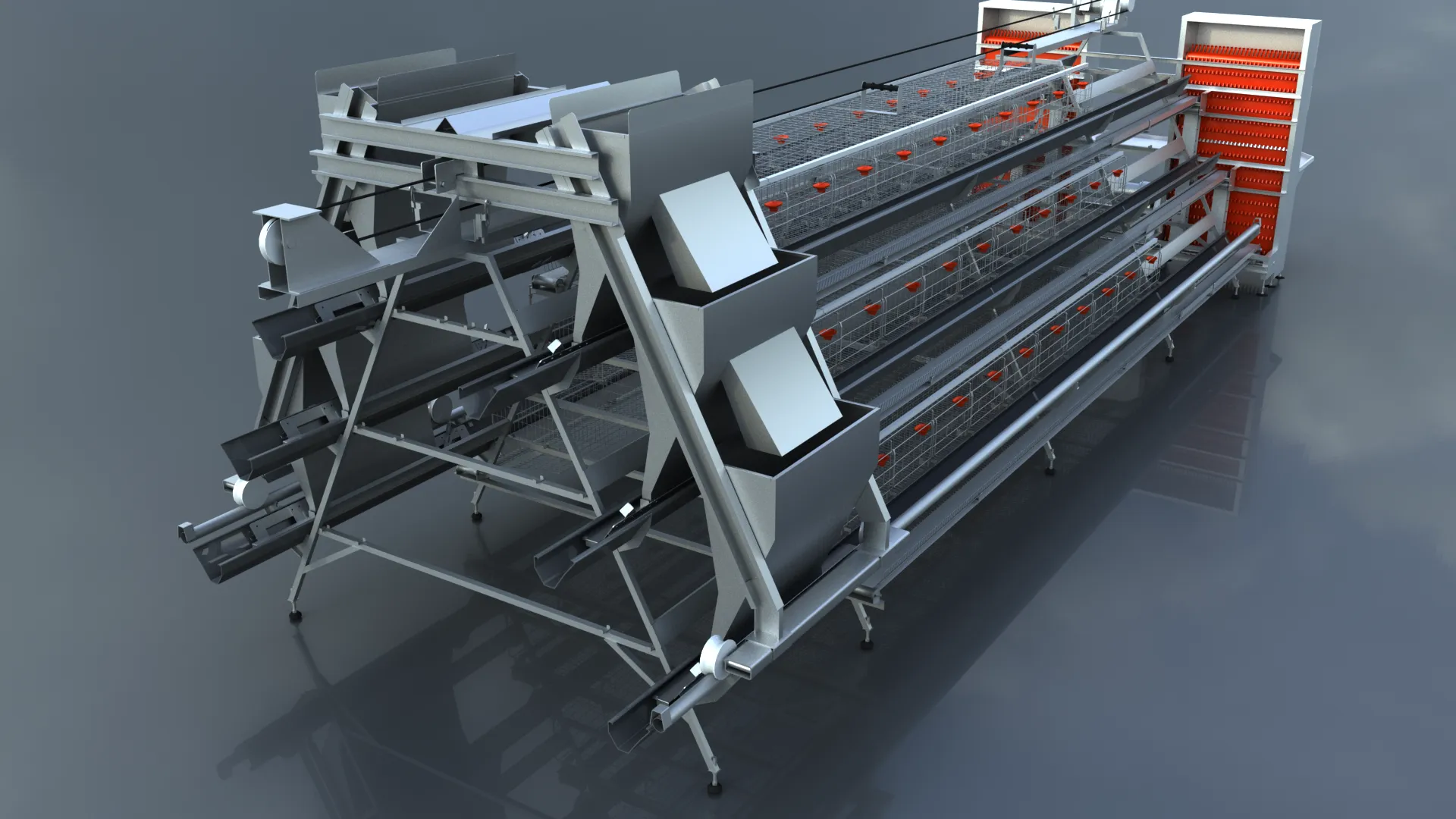

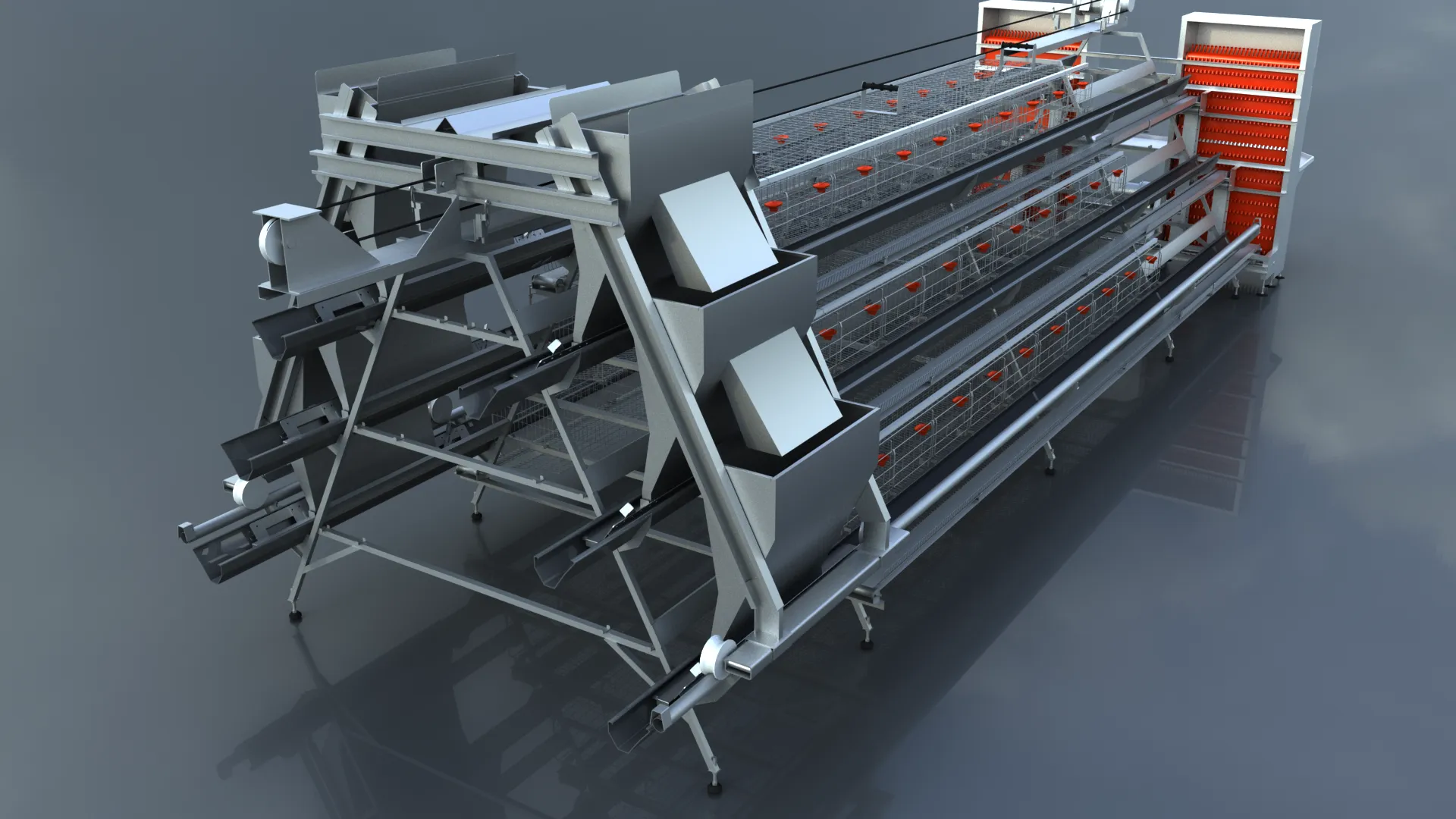

A layer chicken cage is a specialized cage system designed to house laying hens efficiently, ensuring high egg production, minimal labor, excellent manure management, and optimal space utilization for medium to large poultry farms. Its structured tiers, durable materials, and integrated feeding, drinking, and egg collection systems make it ideal for commercial poultry operations seeking automated, scalable, and hygienic egg production.

What is a Layer Chicken Cage System?

A layer chicken cage system is a structured housing solution designed for raising laying hens (egg-producing chickens) in commercial poultry operations. Typically, these systems consist of multiple tiers (levels) of cages stacked vertically within a poultry house, each holding several birds. This arrangement significantly improves space usage and makes large-scale egg production practical.

Main features include:

- Gaiola de Camadas layout for maximum bird density and efficiency.

- Integrated feeding and drinking systems to support healthy, consistent growth.

- Waste management via smart manure removal systems.

- Materials like arame galvanizado for long service life and corrosion resistance.

- Modular designs: available as Type A layer cage、Layer breeder cage、layer cage、Pullet cage

- Compatibility with automated equipment for egg collection.

When we supply cage systems to clients, we ensure the design meets exact needs—from small-scale poultry producers to large-scale egg production companies.

Why Choose Layer Chicken Cages for Your Poultry Farm?

Layer chicken cages are the gold standard for poultry farm operators aiming to maximize efficiency and profit.

Major benefits include:

- Increased egg production: The cage system reduces stress for laying hens, leading to consistent, higher yields.

- Optimal poultry management: Each chicken cage provides controlled feeding, drinking, and manure collection, making large flocks easier to manage.

- Space-efficient: Multi-tier cage designs allow you to house more birds in the same footprint, perfect for expanding output without building new chicken coops.

- Improved hygiene & health: Easy manure removal means less disease, fewer pests, and healthier birds.

- Lower labor costs: Automation (feeding, drinking, manure, and egg collection) means less manual work and faster payback

“By switching to a modern layer chicken cage system, an international egg producer increased flock capacity by 25%, halved labor costs, and improved egg collection efficiency within six months.”

Still unsure? Contact our team for customized poultry cage solutions and see how our engineering expertise supports your growth.

High-Density Poultry Housing for Efficient Egg Production

LAYER CAGE – BH600

- A estrutura laminada apresenta um design razoável e uma estrutura resiliente, então os pássaros terão uma baixa taxa de mortalidade. A alimentação de alta densidade economiza terra e custo.

- O sistema de colheita de ovos apresenta operação estável, baixa taxa de quebra de ovos, operação conveniente e alto grau de automação.

- O equipamento de filtro frontal garante água limpa, com 2 bicos em cada gaiola, bom fornecimento de água e conveniência para beber.

- O sistema de limpeza de esterco apresenta alta resistência à corrosão e design estrutural razoável, garantindo que a correia de esterco fique limpa.

- O sistema de controle climático é altamente automatizado e inteligente, proporcionando um bom ambiente de vida para as aves, o que pode reduzir a taxa de mortalidade das aves e melhorar a taxa de produção dos ovos.

LAYER CAGE-BHLCS625

- A estrutura laminada apresenta um design razoável e uma estrutura firme e confiável. A alimentação de alta densidade economiza terreno e custos.

- O sistema de colheita de ovos apresenta operação estável, baixa taxa de quebra de ovos, operação conveniente e alta automação.

- O equipamento de filtro frontal garante água limpa, com 2 bicos em cada gaiola, bom fornecimento de água e conveniência para beber.

- O sistema de limpeza de esterco apresenta alta resistência à corrosão e design estrutural razoável, garantindo que a correia de esterco fique limpa.

Gaiola de camada tipo A

Gaiola de camada tipo A

| Caraterística |

A-Type Cage |

|

| Estrutura |

Simple, inclined |

|

| Tiers |

3-4 |

|

| Automatização |

Manual/semi-automatic |

|

| Capacity |

2,000–10,000+ birds |

|

| Space utilization |

Good (requires more area) |

|

- A-type cages are ideal for medium-size poultry farms or those starting with basic automation.

Um equipamento de gaiola de camada em série é uma gaiola de alto desempenho de custo projetada pela Qingdao Big Herdsman, adequada para áreas de alta temperatura e confiável. para garantir o máximo de aumento da quantidade de acordo com boa ventilação natural. a gaiola pode ser projetada para 3-4 camadas. Conforme as exigências dos clientes para equipar o sistema de limpezade de esterco e de alimentação para realizar a instalação e produção do equipamento.

- PVC thickened trough,more durable;

- Aluminized zinc wire welding mesh,better corrosion resistance;

- The whole welding galvanized frame,higher strength,better corrosion resistance;

- Auto drinking system,clean,more convenient epidemic

Para garantir os melhores efeitos na criação de frangas, o sistema é caracterizado pelo seguinte:

- Conceção científica: espaços de alimentação amplos e portas de empurrar para dentro para facilitar o manuseamento dos pintos.

- Alimentação eficiente: Um sistema de alimentação com carrinho assegura uma distribuição rápida e uniforme da alimentação.

- Adjustable drinking line: Height-adjustable drinking line adapt to chicks’drinking habits and growth stages.

- Limpeza automatizada do estrume: O sistema de limpeza simplificado e eficiente garante um ambiente higiénico.

- Smart Environment Control: Fully automated systems adjust to different growth phases,providing optimal conditions

Produção de ovos

Manure Management in Layer Chicken Cages

Effective manure removal is a must for hygiene, environmental safety, and flock wellness.

How modern cage systems handle manure:

- Transportador de esterco externo: Nosso transportador externo de esterco garante a remoção eficiente de resíduos de aves com opções de transporte adaptáveis — subterrâneo, acima do solo e aéreo. Apresentando uma estrutura galvanizada a quente, resistência à corrosão e uma estrutura antidesvio, ele oferece desempenho confiável em condições complexas de fazenda.

- Transportador de esterco interno: Otimize o gerenciamento de resíduos de aves com nosso transportador de esterco interno. Apresentando uma estrutura galvanizada a quente, resistência à corrosão, correia antiderrapante e estrutura antidesvio, ele garante a remoção eficiente de esterco em condições complexas de fazenda, mantendo a higiene e a durabilidade.

- Benefits:

- Cleaner environment.

- Lower disease and parasite risk.

- Potential for commercial fertilizer sales.

How to Ensure Proper Ventilation and Lighting in Chicken Houses?

Healthy laying hens need more than just the right chicken cages—they require ideal air flow and lighting for optimal output.

Proper ventilation:

- Keeps temperature and humidity stable inside the chicken house.

- Reduces harmful gases from manure, like ammonia.

Modern solutions:

- Big Herdsman’s fans, featuring stable quality, sufficient air volume, energy conservation and reliability, to completely satisfy your breeding needs.(See our ventilador )

Lighting:

- Consistent, adjustable lighting aligns with poultry circadian rhythms, increasing feed conversion and egg yield.

Tip: Install controllers for lighting systems and climate management for best results.

FAQs About Layer Chicken Cages

What’s the ideal tier number for large-scale poultry farms?

H-type cages with 4–8 tiers are optimal for maximizing bird numbers while maintaining ventilation and access.

How do cage systems help reduce labor costs?

By fully automating feeding, drinking, manure removal, and egg collection, one worker can easily manage thousands of chickens.

Are these cages suitable for raising pullets or only laying hens?

While designed for laying hens, we also manufacture pullet cages for younger birds.

Is there customizability for farm layout?

Absolutely. Modular cage frame designs allow you to match any chicken house dimension or style.

How do you ensure animal welfare?

Our cage mesh, feeder/nipple placement, and automatic systems offer comfort, reduce stress, and support healthy growth. Regular upgrades and technology innovations mean higher welfare standards.

Bullet Point Summary: Key Takeaways

Further Reading

For world-class, durable equipment for your poultry farm, including advanced battery cage systems, rely on a livestock breeding equipment manufacturing partner devoted to quality, technology, and ongoing customer service. Contact us to build a sustainable, profitable, and future-ready poultry operation.