Are you facing persistent issues with poor air quality in your poultry house? It can stress your broiler flocks, reduce production, and inflate energy bills. Fortunately, there is a proven solution. A well-designed ventilation system alleviates these troubles and restores optimal living conditions for your poultry.

A poultry house ventilation system uses controlled mechanical ventilation and air inlet strategies to circulate fresh air, stabilize humidity, and remove excess heat. This balanced air flow reduces stress on birds in both hot weather and cold climates. Ultimately, it fosters healthier flocks, better productivity, and improved profit margins.

Minimum ventilation refers to the minimum amount of ventilation needed to keep the environment habitable during cold weather ventilation. When outdoor temperatures drop, maintaining proper ventilation in the poultry house without causing a chill is critical. Minimum ventilation rates help remove carbon dioxide, ammonia, and moisture while retaining enough heat.

A poultry house ventilation system that employs minimum ventilation settings prevents damp litter, excessive humidity, and the build-up of harmful gasses inside the house. This approach is indispensable for balanced flock health and steady productivity.

Mechanical ventilation uses powered fans, air inlet vents, or blowers to move ventilation air. In contrast, natural ventilation depends on wind and thermal buoyancy through side curtains, doors, or ridge ventilation. Both systems can be part of the ventilation system, but their effectiveness varies with climate, poultry house construction, and farm management practices.

Types of Negative Pressure vs. Positive Pressure

Choosing the best ventilation approach often depends on local climate, building design, and the ventilation requirements set by bird density. Some producers utilize combined ventilation—a tunnel system for summer and minimum ventilation for winter.

An air inlet is where air into the house first passes. The positioning and design of these inlets, whether on sidewalls or the ceiling, significantly impacts air flow. Regardless of your poultry farm size or location, well-placed inlets prevent drafts, regulate ventilation rate, and help maintain consistent temperature.

Pressure Systems for Proper Ventilation

One key facet of poultry house ventilation is managing pressure inside the house:

Quick Tip: Pair an exhaust fan with an air inlet-curtain system to maintain stable conditions in both hot weather and cold seasons. This helps keep your flocks comfortable and results in more uniform bird growth.

If you want a robust inlet setup, consider these Curved Panel Air Inlet Solutions for better house ventilation and consistent air flow.

Broiler chickens are sensitive to fluctuations in humidity and temperature. High moisture fosters bacteria and increases ammonia. Low humidity can lead to dusty conditions. Balancing these factors requires careful calibration of your mechanical ventilation systems. By adjusting fan speeds, inlets, and vents, you can maintain optimal air inside the house.

Cold Weather and Hot Weather Challenges

In both conditions, the system must facilitate ventilation helps remove stale air and moisture. The environment inside the poultry house remains stable for your broiler flocks year-round.

When raising birds at scale, mechanical ventilation systems can be vital for continuous control. These systems work by regulating ventilation rate, which is crucial to meet required ventilation for different stages of growth. Ventilation in poultry houses isn’t just about blowing in fresh air; it’s about balanced inlets, consistent climate, and preventing negative pressure ventilation extremes.

Systems for Cold and Hot Weather

Given the importance of ventilation, advanced controls can measure temperature, humidity, and even ammonia. For a tech-savvy approach, check out this Smart Farm Net solution, which automates climate management for better bird performance in poultry production.

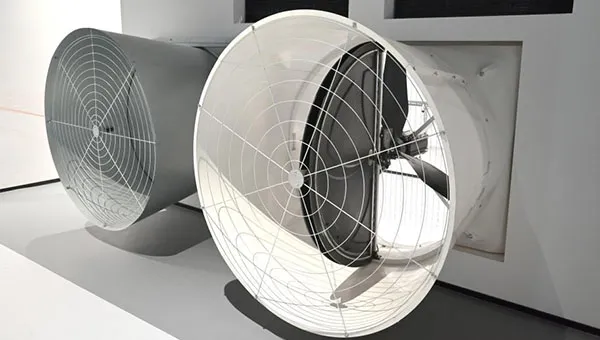

Choosing the right gear—fans, inlets, controllers—ensures ventilation design effectively circulates air inside the house. Proper selection also avoids back-pressure on the fan and enhances the longevity of your setup.

Poultry Ventilation Equipment Checklist

вентилятор

For reliable fans designed specifically for livestock buildings, consider 57 Butterfly Permanent Magnet Fan (Plastic Fan) This ventilation equipment helps maintain consistent conditions inside your ventilated poultry houses.

How do I determine if my poultry house has good ventilation?

Look for steady, comfortable temperatures, low ammonia levels, and non-damp litter. If birds spread evenly and have normal activity levels, that’s a sign of adequate airflow.

What is negative pressure ventilation in a poultry house?

Negative pressure ventilation is a setup where fans draw air out of the facility, creating a partial vacuum. This vacuum pulls fresh air in through regulated air inlet openings, ensuring better air mixing and removal of stale air.

Can tunnel ventilation be used year-round or just for summer?

Tunnel ventilation is often used in warmer months to regulate high temperatures. However, some producers integrate a combined ventilation approach—tunnel for hot months and side inlets for cold weather ventilation. This strategy adapts to seasonal changes.

Is it expensive to install mechanical ventilation systems?

While initial setup costs can be higher than natural airflow, mechanical ventilation systems provide improved climate control, especially in extreme climates. Over time, healthier flocks and better production can offset these costs.

What are the types of negative pressure typically used in poultry houses?

It’s generally one system that uses exhaust fans to reduce pressure. Various levels of static pressure can be applied to control air entering different parts of the house. Adapting fan speed and air inlet positioning helps achieve the target environment.

What is the role of ventilation design in a poultry barn?

Ventilation design ensures balanced airflow, air exchange, and consistent climate throughout the house. It prevents drafts, reduces bird stress, and improves disease control.